|

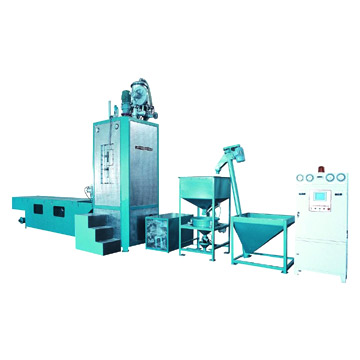

Shanghai Zhongji EPS Machinery Co., Ltd.

|

Plastic Machinery

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Features:

1) Uses PLC programmable controller and touch screen to realize man-machine dialog

2) Uses charging device of automatic negative pressu

Features:

1) Uses PLC programmable controller and touch screen to realize man-machine dialog

2) Uses charging device of automatic negative pressure, electric weighing, and level

switch to realize automatic feeding and gauge

3) Uses auto-controller of temperature and pressure in the chamber and photoelectric

level material to realize the uniform and light density of the beads

4) EPS beads is formed in the auto-cycle by shock sieve, crushing and transportation

fan

5) Uses imported steam reducing valve and proportional valve (optional) to ensure

the stable pressure of the reducing valve outlet, and the temperature tolerances

within ±1°C in the chamber. If the block density is above

30kg/m3, the proportional valve should be installed

6) Hot air drying system (patented) in the fluidized beds with temperature up to

75°C ensures the EPS raw material drying and fast molding, speeds up the

aging process and shortens the production cycle

1) Uses PLC programmable controller and touch screen to realize man-machine dialog

2) Uses charging device of automatic negative pressure, electric weighing, and level

switch to realize automatic feeding and gauge

3) Uses auto-controller of temperature and pressure in the chamber and photoelectric

level material to realize the uniform and light density of the beads

4) EPS beads is formed in the auto-cycle by shock sieve, crushing and transportation

fan

5) Uses imported steam reducing valve and proportional valve (optional) to ensure

the stable pressure of the reducing valve outlet, and the temperature tolerances

within ±1°C in the chamber. If the block density is above

30kg/m3, the proportional valve should be installed

6) Hot air drying system (patented) in the fluidized beds with temperature up to

75°C ensures the EPS raw material drying and fast molding, speeds up the

aging process and shortens the production cycle

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Injection Plastic Molding Machinery

Plastic Injection Molding Machinery

Use Machinery Plastic

Plastic Processing Machinery

Plastic Packaging Machinery

Plastic Pipe Machinery

More>>